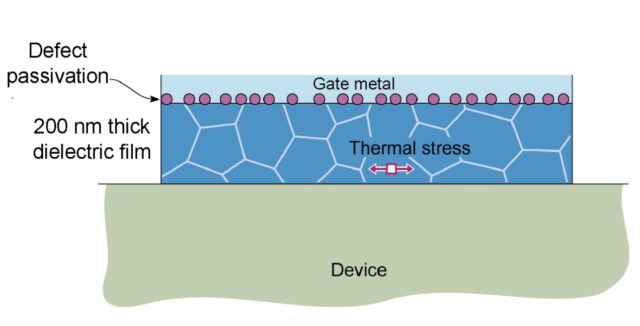

Laser Thermal’s SSTF-F measures thermal conductivity using the combination of laser based thermoreflectance techniques with traditional steady-state thermal testing concepts using the Hopkins Analysis. Harnessing decades of knowledge regarding the relationship between temperature and the thermoreflectance of metals, laser heating of a thin metal film on a material of interest allows for determination of the thermal conductivity of the underlying material without knowledge of the material’s heat capacity by probing the response of the metal due to the pump. These concepts, laser based pμmp-probe experiments, have been utilized for decades to measure various optical, mechanical, and thermal properties of materials.

Unlike most traditional free-space (exposed laser beams) pump-probe experiments, SSTR-F incorporates all of its active and passive components in fiber-optic leading to a compact, simple system with increased safety, no need for prior optical experience, and streamlined high throughput measurements.

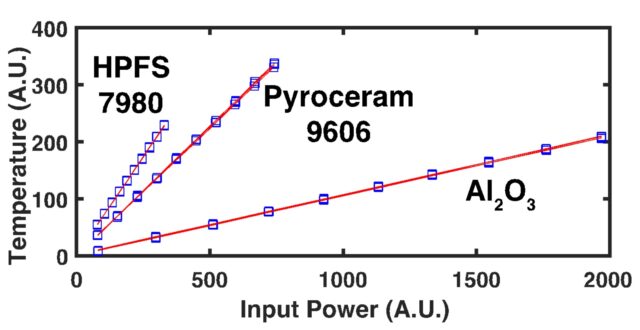

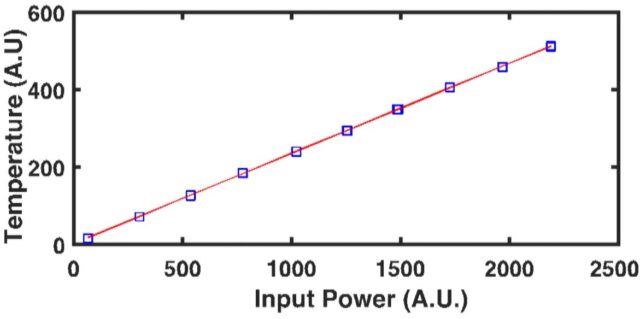

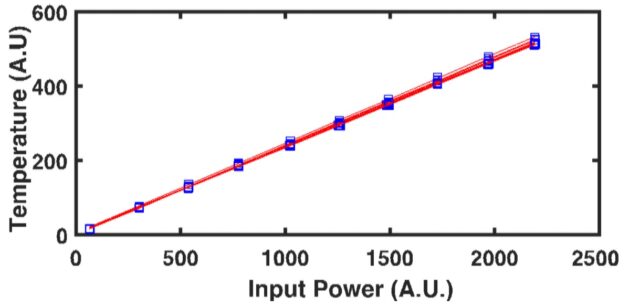

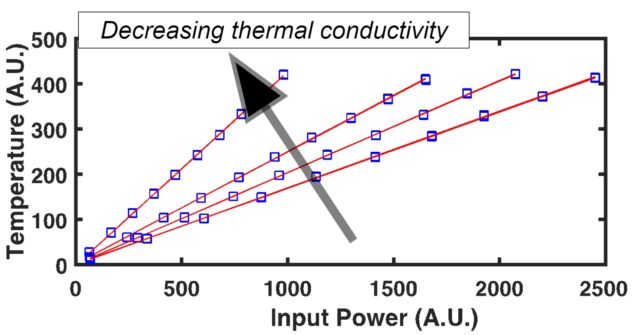

The technique works in principle by inducing a steady-state temperature rise in a material via long enough exposure to heating from a pump laser. A probe beam is then used to detect the resulting change in reflectance, which is proportional to the change in temperature at the sample surface. Increasing the power of the pump beam to induce larger temperature rises, Fourier’s law is used to determine the thermal conductivity.